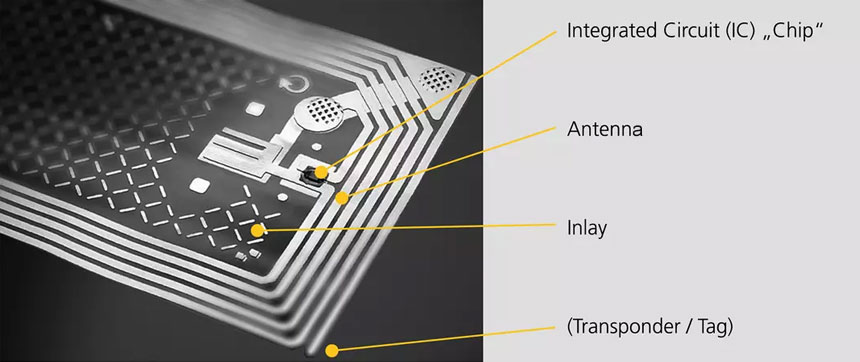

In the process of wireless communication, the RFID tag antenna is an indispensable component, and Radio-frequency identification (RFID) uses radio waves to transmit information, and the generation and reception of radio waves need to be realized through the antenna. When the RFID tags enter the working area of the RFID reader/writer antenna, the passive RFID antenna will generate enough induced current to obtain energy to be activated.

For the RFID system, the RFID tag antenna is a vital part, and it is closely related to the performance of the system.

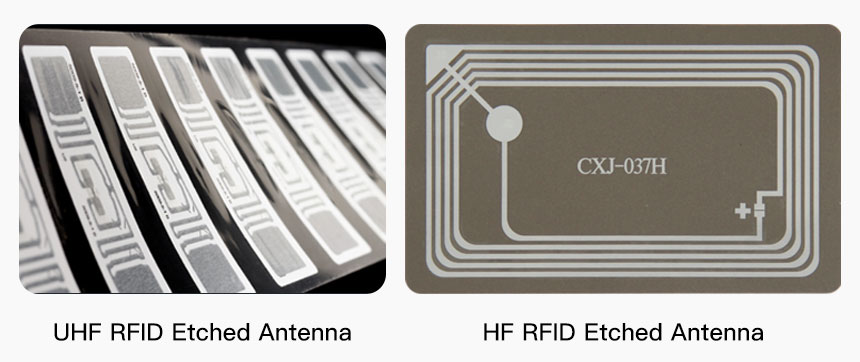

At present, according to the differences in RFID chip antenna wire material, material structure and manufacturing process, RFID tag antennas can be roughly divided into the following categories: etched antennas, printed antennas, wire-wound antennas, additive antennas, ceramic antennas, etc. The most common antenna manufacturing processes are the first three.

| Process Types | Overview | Application | Characteristics |

| RFID Etched Antennas | Etching often uses copper or aluminum to make RFID antennas, which is close to the etching process of printed circuit boards in the production process. | Mostly used in high frequency RFID systems | High precision, high cost, low capacity. |

| RFID Printed Antennas | The printed antenna is a circuit in which conductive ink is directly printed on an insulating substrate (or film) to form an antenna circuit. | Generally used in UHF and HF RFID systems. | Low cost, large output, and low durability. |

| RFID Coil Antennas | Wind the label coil on a winding tool and fix it. Generally, there are more copper wires and more coil turns. |

Generally used in low-frequency RFID systems, high-frequency RFID systems can also be used. |

High cost and slow production speed. |

But the etching process uses a chemical corrosion reaction, there are problems of long process flow and a lot of waste water, which easily pollutes the environment. Therefore, the industry has been working hard to find better alternatives.

Directly use special conductive ink or silver paste to print or print the antenna circuit on the substrate. The more mature one is gravure printing or silk screen printing. Screen printing saves costs to a certain extent, but its ink uses about 70% high-silver conductive silver paste to obtain antennas between 15 and 20um, which is a thick film printing method with high cost.

The manufacturing process of the copper coil RFID tag antenna is usually completed by an automatic winding machine. The insulating paint is directly wound on the base carrier film, and the copper wire with a low melting point baking varnish is used as the base material of the passive RFID tag antenna. Finally, the wire and the substrate are mechanically fixed with an adhesive, and a certain number of turns are wound according to different frequency requirements.

RFIDSilicone is one of the top and reliable RFID tag manufacturers in Shenzhen China and has its own 7s managed RFID factory.

Welcome to consult and make an appointment to visit and inspect the factory online. We provide online video real-time live broadcast of the factory introduction.

How to make an appointment to visit the RFIDSilicone factory online?

You can contact us in the following ways:

1. Send an email to info@rfidsilicone.com;

2. Send message or call to Phone/Whatsapp: +86 13612933572;

3. Add official Skype: live:cxjrfid