The waterproof silicone RFID wristbands are a smart radio frequency card that is easy to wear on the wrist. The RFID wristband tag is made of environmentally friendly silicone material, which is comfortable to wear, beautiful in appearance and decorative. Can be applied to Metro Card, catering consumption, attendance management, swimming pool, washing center, sauna center and entertainment venues, airport parcels, parcel tracking hospital patient identification, childbirth, infant identification and prison management, guardianship management, personnel location and so on.

In the process of making waterproof RFID silicone wristbands, may be used of laser engraving, glue, oil injection, printing and other processes.

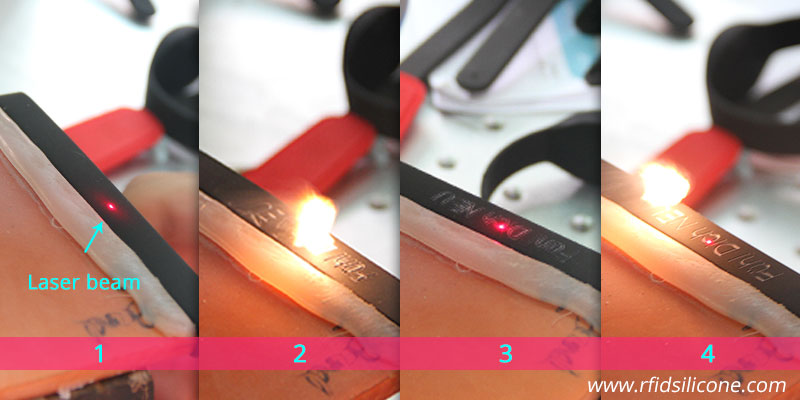

Laser engraving, also called laser engraving, is a process of surface treatment using optical principles. The light energy of the laser beam causes the chemical and physical changes of the surface layer to mark the trace, or the light energy burns off some of the material to reveal the pattern and text to be etched.

First, the silicone wristband product is molded, and then the product is filled with glue. The composition of the glue is mainly composed of an adhesive colloid and an organic solution. The role of the adhesive colloid is to act as an adhesion. The organic solvent refers to a low-toxic, volatile chemical solvent capable of melting the adhesive colloid, such as cyclohexanone, gasoline, acetone, methyl ethyl ketone and the like. In the filling of the glue, the volatilization of the organic solution is mainly relied on to achieve the expansion effect of the sponge. Therefore, when filling the glue, try not to expose the sponge with the glue to the outside, so that the expansion effect of the organic solution on the sponge will be reduced.

Silicone protective ink (matting oil, soft hand oil, dumb oil) is a coating protective ink used on silica gel materials. It is applied to the surface of silicone buttons to improve gloss and improve hand and font life. The product after matting treatment has the characteristics of smooth hand feeling, matte surface and high abrasion resistance, which can protect the printed font on the silicone rubber button and protect the surface of other silicone rubber products from dust. effect.

Silicone printing is simply printed by means of silk screen printing. The mesh of the screen printing plate can be printed through the basic principle of the silica gel and the non-image part of the mesh is not transparent. A certain pressure is applied to the silica gel by the squeegee to squeeze the silica gel from the mesh of the image portion onto the substrate

RFIDSilicone.com has developed RFID wristbands: customized color RFID silicone wristband, RFID PVC wristband, RFID nylon wristband, RFID plastic wristband, RFID disposable PVC wristband, RFID disposable paper wristband, RFID watch wristband, RFID grow in dark LED wristband etc. Please feel assured to purchase!