In today's fast-paced world, the RFID tag is a powerhouse of efficiency for inventory management, asset tracking, and seamless retail experiences. Yet, with countless RFID tag options flooding the market, making the wrong choice can lead to system failures, wasted budgets, and operational headaches. How do you navigate this complex landscape to find the perfect match for your project? This guide cuts through the noise, providing a systematic, step-by-step framework to ensure you select the right RFID tag every time.

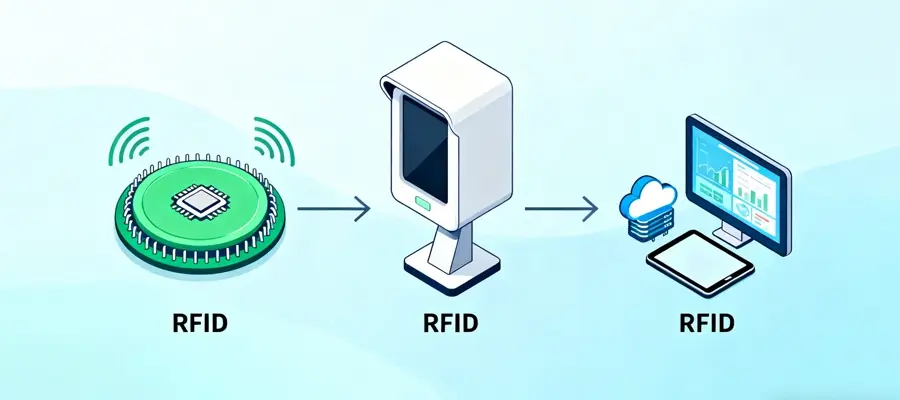

Before choosing an RFID tag, it's crucial to understand the ecosystem it operates within. An RFID system consists of three core components: the tag itself, a reader/interrogator, and software. The RFID tag is the data carrier attached to your item.

Low Frequency (LF - 125-134 kHz): Offers short read ranges (a few centimeters) and high resistance to interference, especially from metals and liquids. Common uses: animal tracking, access control.

High Frequency (HF - 13.56 MHz): Provides medium read ranges (up to ~1 meter). Ideal for applications requiring higher data security and slower, one-at-a-time reading. Common uses: library books, smart cards, payment systems.

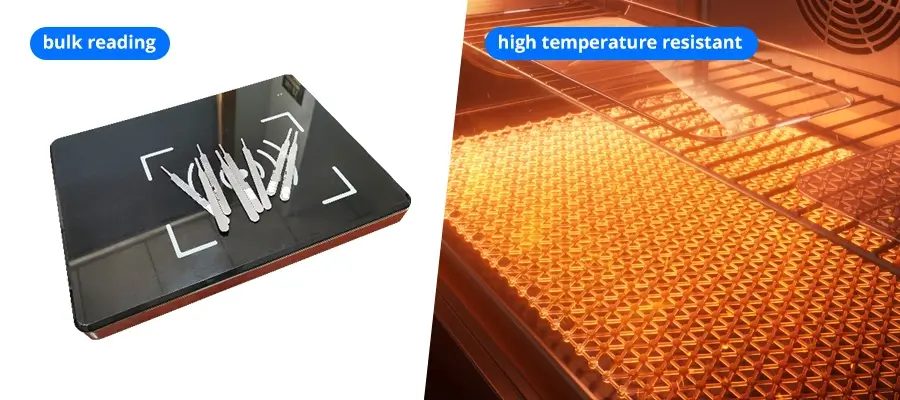

Ultra-High Frequency (UHF - 860-960 MHz): Delivers long read ranges (1-12+ meters) and can read hundreds of tags per second simultaneously. The standard for supply chain, retail, and logistics. Performance can be affected by metals and liquids.

Passive RFID Tags: Have no internal battery. They are powered by the radio wave energy from the reader. They are smaller, less expensive, and have a virtually unlimited lifespan. Most common RFID tag type.

Active RFID Tags: Contain a battery to power their transmissions, enabling very long read ranges (100m+) and additional features like sensors. They are larger and more expensive.

Semi-Passive (BAP) Tags: Use a battery to power the chip but communicate using backscatter like passive tags, offering a balance of range and longevity.

Choosing an RFID tag isn't about finding the "best" one—it's about finding the most suitable one. Systematically evaluate these five core dimensions.

Core Question: What problem are you solving?

Examples: Retail inventory counts, parcel tracking in logistics, tool management on a factory floor, file management, vehicle access control.

Impact: This directly dictates required read range, speed, and tag volume (bulk reading vs. single-item reading).

This foundational assessment ensures your RFID tag will function at all.

Item Surface Material:

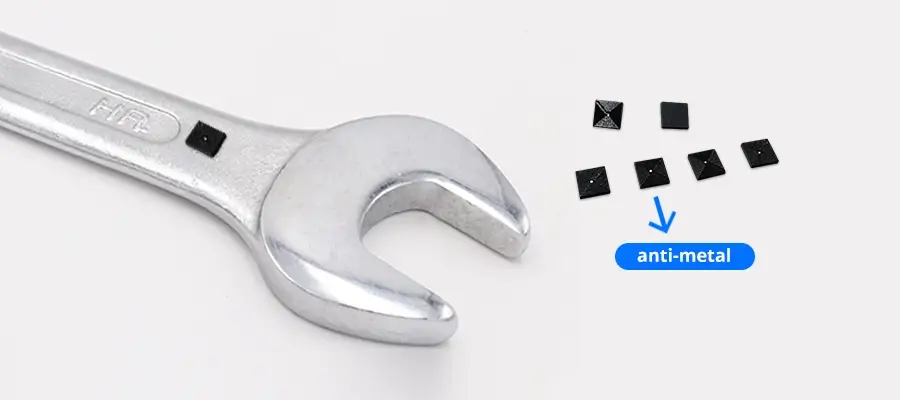

Metal: Causes signal interference/detuning. You must choose a dedicated metal-mount RFID tag with a special isolation layer.

Liquids/High-Moisture: Absorb UHF signals. Choose liquid-optimized tags or consider HF.

Plastic, Wood, Cardboard: RF-friendly. Standard paper/polyester labels often work well.

Item Size & Tag Form Factor:

Small Items: Require micro RFID tags (cable, film) to avoid impacting form/function.

Large Items: Can accommodate larger tags for greater range and durability.

Mounting Method:

Adhesive: Most common. Consider adhesive properties (permanent vs. removable, chemical/heat resistance).

Embedded/Implanted: For tools, wood, animals. Requires rugged encapsulation.

Hanging/Punched Hole: For garment hang tags, asset labels.

Epoxy/Screw Mount: For heavy-duty assets in extreme environments.

Read Range & Speed: Define operational needs. Is it hands-on proximity (HF) or high-speed dock door reading (UHF)?

Memory Capacity:

ID Only (EPC): Sufficient for a unique identifier (96-128 bits). Most tags qualify.

User Memory: Needed to store writable data like maintenance history, requires a tag with dedicated memory (bytes to kilobytes).

Read/Write Capability:

Read-Only: Factory-programmed, immutable ID. Lowest cost.

Read/Write: Data can be updated post-issuance. Essential for dynamic data.

Extreme Temperatures: Freezer (-40°C) or paint shop (>200°C) applications need specially rated tags.

Chemical Exposure: Resistance to oils, solvents, or frequent sterilization.

Physical Abuse: Vibration, abrasion, impact require flexible or hardened materials.

Outdoor Weathering: UV protection, water/dust ingress protection (IP Rating).

Total Cost of Ownership (TCO): Includes tag price, application labor, software integration, and maintenance.

Regulations & Standards: Must comply with local radio frequency regulations (FCC, CE, etc.) and industry standards (ISO/IEC, RAIN RFID).

Selecting the right RFID tag is only half the battle. Without robust software to manage and interpret the data, you won't realize a return on investment. Evaluate software for these key features:

Core Data Management: Device monitoring, batch tag encoding/commissioning, and data filtering/aggregation.

Integration & APIs: Seamless connectivity to existing WMS, ERP, or custom applications via middleware or robust APIs.

Visualization & Analytics: Real-time dashboards for KPIs and historical reporting for insights like inventory turnover.

Scalability & Security: Architecture that grows with you and enforces strict data access controls.

Adhesive Labels (Paper/Plastic): Cost-effective for boxes, cases, books.

Epoxy/ Ceramic Tags: Withstand high heat and are often used for metal asset tracking.

Flexible Fabric Tags: Sewn into garments, linens.

Specialized Forms: Screw-on, key fob, card (credit card size), washer, and tool tags.

Specialized RFID tags use materials or air gaps to isolate the antenna from disruptive surfaces, ensuring reliable performance on metal or near liquids.

Balance the size of the RFID tag with your read range needs and space constraints. Installation must be secure for the item's lifecycle.

(You can find more information about RFID tags and RFID technology products, including pictures, features, and applications, on this website. Even if you don't find a product that perfectly matches your needs, feel free to contact us for inquiries.)

Define Your Objective: What specific process are you improving?

Assess the Environment: Identify all physical and RF constraints (material, size, space, interference).

Determine Performance Needs: Quantify required read distance, speed, and data.

Match to Tag Type: Use the factors above to filter available RFID tag options.

Conduct Pilot Testing: This is non-negotiable. Test shortlisted tags in your real-world environment.

Evaluate Vendor & Support: Assess reliability, technical support, lead times, and sample policies.

Retail & Apparel: Low-cost UHF adhesive labels or woven fabric tags.

Logistics & Warehousing: Durable UHF labels for cases/pallets; hard tags for reusable containers.

Manufacturing & Asset Tracking: Rugged on-metal UHF tags, often with screw or epoxy mounting.

Healthcare & Pharma: Small HF or specialty UHF tags for compliance with sterilization and biocompatibility needs.

Agriculture & Livestock: LF glass capsule tags for animal implantation.

Skipping real-world environmental testing.

Focusing solely on tag price instead of Total Cost of Ownership (TCO).

Choosing an incompatible frequency or protocol for your application.

Underestimating the importance of software integration and support.

Overlooking the required read range in the actual deployment setting.

Smaller & Cheaper Tags: Enabling item-level tagging for more products.

Sensor-Enabled Smart Tags: Integrating temperature, humidity, and shock sensors.

Sustainable Tags: Made from recycled or biodegradable materials.

There is no universal "best" RFID tag. Success lies in a methodical selection process that prioritizes your specific application, environment, and performance needs. Always partner with a knowledgeable vendor and insist on thorough pilot testing. By following this guide, you're equipped to make an informed decision that will deliver efficiency, visibility, and ROI.

-------------------

Welcome to contact us!

RFIDSilicone is Your Best RFID & NFC Partner!

19+ years experience in RFID products (RFID wristband, RFID sticker/tag, RFID card etc).

Our own factory passed ISO9001: 2015 & ISO14001:2015. We have SGS, ROHS, REACH, FDA certificates etc.